The use of mesh on the vibrating screens is for the purpose of segregation and classification of objects. Each wire has its own specific location within the interlaced mesh structure. The vibrating screen mesh has a supporting and tensioning function to uphold the screen panels in order to get a free and efficient vibrating movement.

Vibrating screen mesh is used in mining, aggregate manufacturing, recycling, and chemical industries where it is used to separate a solid material such as sand, gravel, and crushed stone. It gives the material a classification based on size and then only allows the passage of desirable particles while retaining the bigger particles. This method enhances the product quality and helps to maintain uniformity.

The Importance of Understanding Vibrating Screen Mesh Anatomy

Correct screening is a function of mesh anatomy (screening surface configuration). Operators can become more proficient in the vibrating screen by learning about the parts and processes that make the vibrating screen work well.

The anatomy of vibrating screen mesh prevents downtime and at the same time, reduces maintenance costs. What mesh is built of and how it is woven with other units is a question that operators should understand. They will be able to predict problems in advance when something is damaged or broken. This enables the prompt maintenance or substitution of worn-out parts, thus avoiding expensive breakdowns.

The Basic Components of Vibrating Screen Mesh

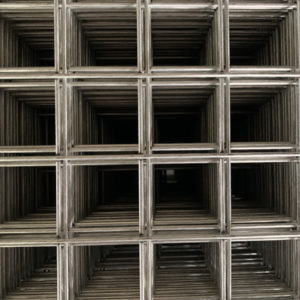

Generally, woven wire is the widely used vibrating screen mesh. The wires are interlaced into the box or rectangle. Mesh wires are generally made of steel, with stainless steel or high-carbon steel being the most common. This is because of their strength and durability.

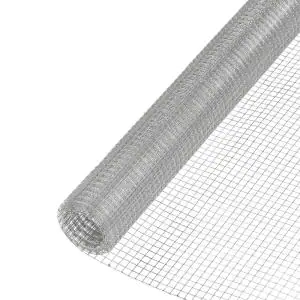

As opposed to woven wire mesh, crimped wire mesh has crimped edges which are meant to secure the screens. Such applications as heavy-duty equipment that require high vibration frequencies and impact resistance use this mesh.

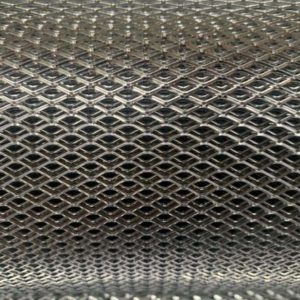

Another alternative is chute plates, which are flat sheets with holes on the surface. The diameter and shape of the hole vary according to the application. Perforated plate screens are fine-screened and dewatered.

Understanding the Role of Woven Wire Mesh in Vibrating Screen Mesh

The woven wire mesh vibrating screen mesh has numerous advantages and, therefore, is widely used. Firstly, steel has excellent performance, which means that it is a great choice for heavy-duty work. It could withstand strong vibration and impact influence without getting deformed.

Firstly, braided wire mesh proves to be an effective screening mechanism because it lets the particles of the intended size pass through, but the larger ones are kept. The mesh screen weave has been designed to be open and this allows for efficient operation while at the same time reducing screen viewing obstruction.

The wire mesh is woven from different types of vibrating screens. Each variety has its own unique features. Squares, rectangles, and locks are the most common weave patterns. The most common pattern is the square weave; it is the most fundamental one, with wires braided in squares. Round wires that have rectangular weaving are more stable and well-supported. The lock crimp weave has a structure that is tightly interlaced and has crimped edges, which strengthens and rigidifies the structure.

The Different Types of Weaving Patterns Used in Vibrating Screen Mesh

In weaving, vibrating screen mesh patterns affect mesh performance and features. The filter screen mesh uses plain weave, twill weave, and Dutch weave.

The plain weave is the simplest and most widespread vibrating screen mesh pattern which is woven. Tightly crossover and interlinked, one on top of the other, in a basic crisscross pattern. This knit provides the mesh with the ability to withstand stresses and strains, making it suitable for various applications.

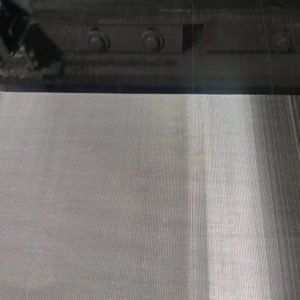

Twill weave refers to a more complex weaving pattern that is composed of wires that cross and under each other. The crisscross way that the mesh is arranged enhances the mesh surface support and stability. The textiles that are utilized in applications that require very high tensile strength and fine screening utilize twill weave.

The Dutch weave relies on using several sizes of weft and warp wire diameters, which is something that is not common. The warp wires are thicker, and the weft is thinner than in the previous machine. Such a dense mesh structure with the tiniest pores is ideally suited for the precise filtering and separation of particles.

The Significance of Mesh Count in Vibrating Screen Mesh

Fabric count is the number of mesh holes per inch of the screen surface. It is important to weave the process of screening with performance in an efficient way.

A tighter mesh size facilitates precise screening and greater throughput by incorporating more openings in the same area. Higher mesh numbers imply smaller apertures, and these, in turn, shortened the screen life, and blinding and clogging occurred. Consequently, mesh count and screen performance have to be traded off in line with the particular application’s needs.

Holes on the mesh are counted per inch, and thus, the mesh count is derived. A net with 100 holes per linear inch is a 100-count mesh. The number of meshes used in the fabrication process can range from coarse to fine to fit the application.

The Different Materials Used in Vibrating Screen Mesh

The mesh of the vibrating screen can be made from application-specific materials to achieve the desired results. The materials selected are stainless steel, high-carbon steel, polyurethane, and rubber. The vibration screen mesh from stainless steel is widely used because of its corrosion resistance feature and toughness. It is used in the food-processing, mining, and chemical industries.

In addition to the high-carbon steel mesh, another common material is high-carbon steel. It is qualified in the sense that it is strong and abrasion-resistant, which makes it suitable for heavy-duty applications with severe impact and wear. Synthetic polyurethane is flexible but has good abrasion resistance. It is widely used for fine screening and dehydration of water. Vibrating screens frequently use polyurethane mesh, which is simple, fast to set up, and lightweight. Rubber is a material that is very resilient both to abrasion and impact. It is necessary to attenuate the noise or vibration. In this way, rubber mesh is ideal for screening moist or sticky items.

The most used screen mesh is woven wire mesh, which can be strong and efficient too. The plain weave, the twill weave, and the Dutch weave have distinct characteristics and performance advantages. The mesh effectiveness in the vibration screen is mesh count dependent. Decision-makers should select the mesh counts so depending on application needs.

Lastly, depending on the application, corrosion resistance, abrasion resistance, and application-specific criteria determine the choice of vibrating screen mesh material. Rubber, polyurethane, high carbon steel, and stainless steel are the common mesh materials for the vibrating screens.

2 Responses