Screens

In-Stock

Punched Screens

Our wire mesh screens come in both woven and welded wire mesh specifications. Primarily composed of iron and a small amount of carbon, these products are popular because of their widespread use, versatility, and low cost. Wire mesh screens are strong and durable. They come in various materials, including Galvanized Steel and PVC or powder-coated treatment options. The most popular uses include fireplace screens, small guards, infill panels, window guards, shaker screens, wall coverings, and cabinets. They can also be used for machine and equipment guards and separation and filtration.

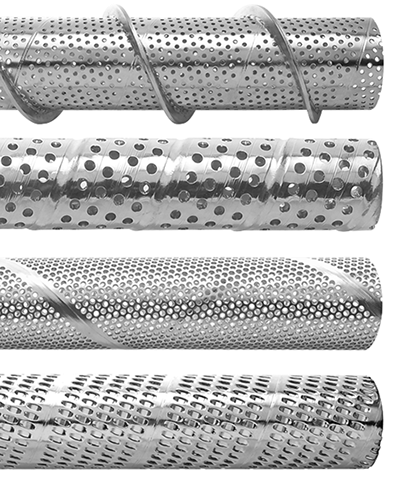

Slip-On Wire Wrap Screen

Slip-On Wire Wrapped Screens are used for various projects to prevent plugging and corrosion. Commonly used as a sand control device, the slip-on screen is positioned over the top of a slotted or perforated base to add mechanical strength to your pipe.

Duke Metal Industries offers various wire profiles, materials, and perforation or slotting patterns to ensure superior sand control performance. Our robust designs help you minimize sand screen installation risks and ensure uniform flow distribution to meet your project requirements.

Description:

- Made from corrosion and plugging-resistant stainless steel

- Offers high flow rate with low-pressure drop

- Custom slotting and perforating patterns available upon request

- Excellent use for various applications, including open-hole standalone completions, secondary liner completions, cased and perforated completions, vertical and horizontal walls, medium to high-velocity wells, and more

- Allows for easy backwashing

Proprietary Manufacturing Technology

Our production methods accommodate product features such as dimples, louvers, and tight restrictions. Our advanced procedures and equipment enable us to adapt to your requirements, optimize production speeds, and improve cost-effectiveness for you.

Our manufacturing process includes custom-designed mills incorporating spiral welding. This helps us to deliver superior quality.

Spiral Welding Advantages

Our spiral welding process is superior to conventional welding. We optimize the process in the following ways:

Flexibility in handling a wide variety of designs/configurations

High strength

Greater rigidity at reduced wall thicknesses

Ability to produce large-OD tubes

Unlimited tube lengths

Production efficiency in short runs

Our production capabilities accommodate a wide range of product designs and sizes. We have multiple modular production lines, each of which can be quickly re-tooled to handle large volumes or special requirements.

Dimensions

Diameters: .625 in. OD (15.875 mm) to

15 in. OD (381 mm)

Wall Thicknesses: .025 in. (.635 mm) to .1875 in. (4.763 mm)

Lengths: Custom lengths, plus stock lengths from 2.5 in. (63.5 mm) to 38 feet (11.582 m)

Materials

Stainless steel and mild carbon steel

Titanium, nickel, and other exotic alloys

Perforation Patterns

Custom hole shapes, sizes, and patterns to suit any open-area requirement

Inventory of standard staggered and in-line patterns

Support Services

We can manage all aspects of production and coordinate any additional services you need:

Design

Component assembly

Inventory management

Shipping logistics

Packing and crating (including export crating)

Heat treating

Electro-polishing

Coatings

Quality

We adheres to stringent quality assurance procedures, including 100% inspection of finished pieces. Every tubing joint receives a thorough examination of ID/OD, weld integrity, straightness, and length. We are also able to validate the micron rating in our finished product.

We will also incorporate any additional quality requirements you may have. Our quality assurance program is fully documented and available for your review.

Material certifications are provided for every order, with complete listings of relevant chemical and physical properties. Every order is fully traceable back to the heat number of the raw material.

Why Choose Us

Duke’s Wire Mesh Supply Services Ltd. is one of the most competitive metal manufacturers in North America. Our products are delivered to more than 160 countries and regions. We are looking forward to offering you high-quality services and goods for unbeatable prices. Call us for a quotation.

In-Stock

Punched Screens

Our wire mesh screens come in both woven and welded wire mesh specifications. Primarily composed of iron and a small amount of carbon, these products are popular because of their widespread use, versatility, and low cost. Wire mesh screens are strong and durable. They come in various materials, including Galvanized Steel and PVC or powder-coated treatment options. The most popular uses include fireplace screens, small guards, infill panels, window guards, shaker screens, wall coverings, and cabinets. They can also be used for machine and equipment guards and separation and filtration.

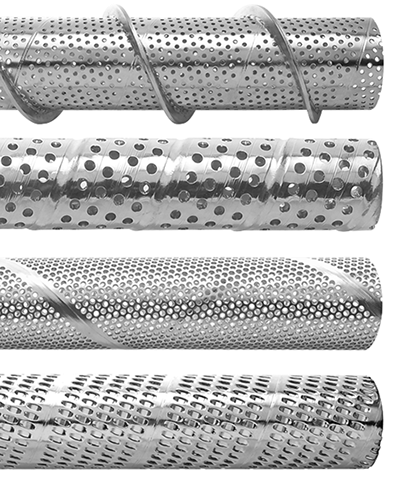

Slip-On Wire Wrap Screen

Slip-On Wire Wrapped Screens are used for various projects to prevent plugging and corrosion. Commonly used as a sand control device, the slip-on screen is positioned over the top of a slotted or perforated base to add mechanical strength to your pipe.

Duke Metal Industries offers various wire profiles, materials, and perforation or slotting patterns to ensure superior sand control performance. Our robust designs help you minimize sand screen installation risks and ensure uniform flow distribution to meet your project requirements.

Description:

- Made from corrosion and plugging-resistant stainless steel

- Offers high flow rate with low-pressure drop

- Custom slotting and perforating patterns available upon request

- Excellent use for various applications, including open-hole standalone completions, secondary liner completions, cased and perforated completions, vertical and horizontal walls, medium to high-velocity wells, and more

- Allows for easy backwashing

Proprietary Manufacturing Technology

Our production methods accommodate product features such as dimples, louvers, and tight restrictions. Our advanced procedures and equipment enable us to adapt to your requirements, optimize production speeds, and improve cost-effectiveness for you.

Our manufacturing process includes custom-designed mills incorporating spiral welding. This helps us to deliver superior quality.

Spiral Welding Advantages

Our spiral welding process is superior to conventional welding. We optimize the process in the following ways:

Flexibility in handling a wide variety of designs/configurations

High strength

Greater rigidity at reduced wall thicknesses

Ability to produce large-OD tubes

Unlimited tube lengths

Production efficiency in short runs

Our production capabilities accommodate a wide range of product designs and sizes. We have multiple modular production lines, each of which can be quickly re-tooled to handle large volumes or special requirements.

Dimensions

Diameters: .625 in. OD (15.875 mm) to

15 in. OD (381 mm)

Wall Thicknesses: .025 in. (.635 mm) to .1875 in. (4.763 mm)

Lengths: Custom lengths, plus stock lengths from 2.5 in. (63.5 mm) to 38 feet (11.582 m)

Materials

Stainless steel and mild carbon steel

Titanium, nickel, and other exotic alloys

Perforation Patterns

Custom hole shapes, sizes, and patterns to suit any open-area requirement

Inventory of standard staggered and in-line patterns

Support Services

We can manage all aspects of production and coordinate any additional services you need:

Design

Component assembly

Inventory management

Shipping logistics

Packing and crating (including export crating)

Heat treating

Electro-polishing

Coatings

Quality

We adheres to stringent quality assurance procedures, including 100% inspection of finished pieces. Every tubing joint receives a thorough examination of ID/OD, weld integrity, straightness, and length. We are also able to validate the micron rating in our finished product.

We will also incorporate any additional quality requirements you may have. Our quality assurance program is fully documented and available for your review.

Material certifications are provided for every order, with complete listings of relevant chemical and physical properties. Every order is fully traceable back to the heat number of the raw material.

Request A Quote

Duke’s Metal Industries is one of the most competitive metal manufacturers in North America. Our products are delivered to more than 160 countries and regions. We are looking forward to offering you high-quality services and goods for unbeatable prices. Call us for a quotation.