Mining Mesh

In-Stock

-

Product Overview

Mining Mesh is a grid of high-strength steel wires welded together at their intersections, forming a robust and reliable reinforcement structure. This mesh is specifically engineered to withstand the harsh conditions of mining operations, offering superior stability and protection.

Product Types

- Flat Sheets

- Sizes Available:

- Various sizes up to 7.5 feet wide and 35 feet long

- Applications: Ideal for reinforcing large surface areas such as mine walls and ceilings, providing excellent support and safety.

- Sizes Available:

- Rolls

- Sizes Available:

- Widths up to 8 feet (2.44 meters)

- Lengths up to 100 feet (30.48 meters)

- Applications: Suitable for flexible applications where ease of transportation and installation is required, such as temporary reinforcements and emergency repairs.

- Sizes Available:

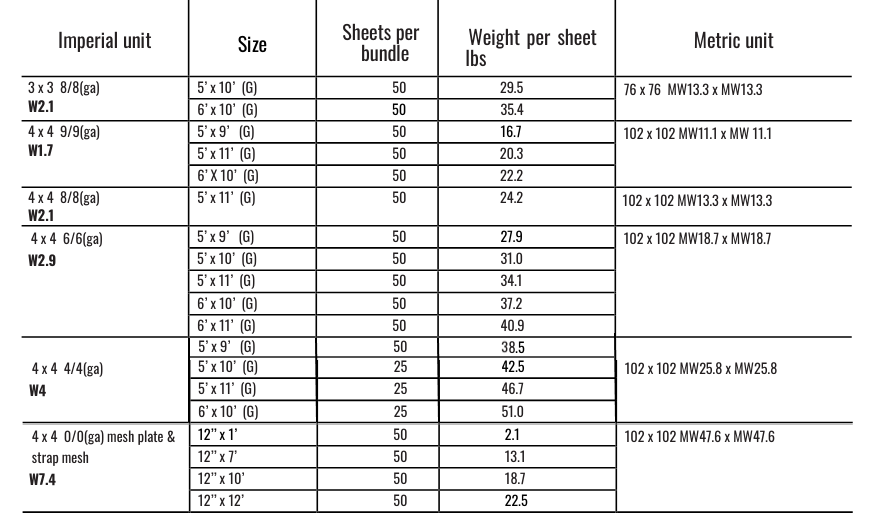

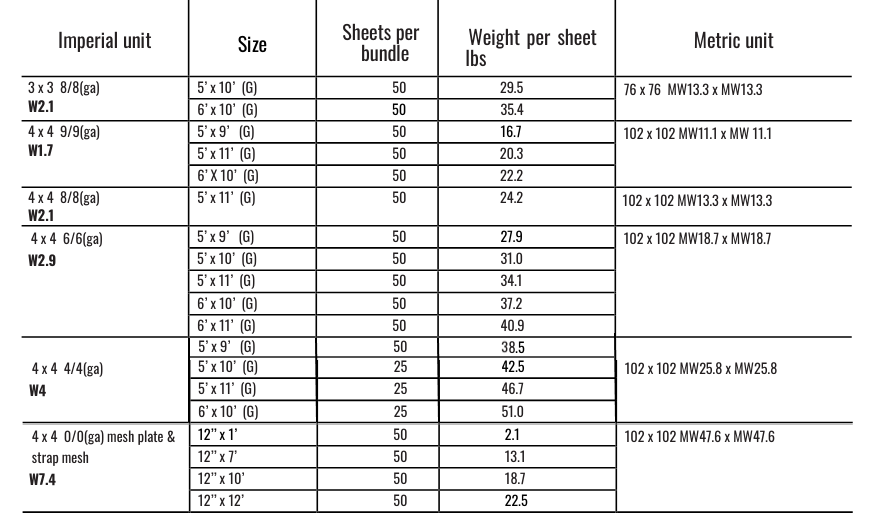

Specifications

- Wire Gauges Available:

- 0 gauge (0.324 inches or 8.23 mm)

- 4 gauge (0.204 inches or 5.19 mm)

- 6 gauge (0.162 inches or 4.11 mm)

- 8 gauge (0.128 inches or 3.26 mm)

- Other thicknesses are customizable

- Mesh Sizes:

- 3×3 inches (75×75 mm)

- 4×4 inches (100×100 mm)

- Custom mesh sizes available upon request

- Materials:

- Carbon steel

- Class 3 galvanized steel according to ASTM A641 standard

- Customization:

- Thickness, opening size, and roll size can all be customized to meet specific project requirements.

Mechanical Properties

- Tensile Strength: Higher than 515 MPa

- Yield Strength: More than 450 MPa

- Welding Shear Strength: More than 50000 times the nominal area of the welded wire in square inches, offering 40% higher welding shear strength than industry standards (ASTM A1064-22)

Product Features

- Flush Cut Ends: Ends protrude no more than 1/8″ and no more than 3/16″ beyond the edge wire

- Third-Party Testing: All products are tested by well-known and reputable third-party testing labs

- Test Results: For detailed test results, please see the ASTM Quality Testimonies page

Installation Tips

- Cutting: Can be easily cut to size using wire cutters or power tools

- Mounting: Use appropriate hardware such as bolts, clamps, or brackets to secure the mesh in place

- Support: For larger spans or critical support areas, additional support structures such as rock bolts or anchors may be needed to prevent sagging or displacement

Compliance and Standards

- ASTM Standards: Manufactured according to relevant ASTM standards to ensure quality and consistency

- ISO Certification: Our production processes are ISO certified, guaranteeing the highest standards of manufacturing

Applications

- Mine Shaft Reinforcement: Provides essential support and stability to mine shafts, preventing collapses and ensuring worker safety

- Tunnel Support: Used in tunneling operations to reinforce tunnel walls and ceilings, offering enhanced structural integrity

- Roof and Wall Support: Offers critical support for roofs and walls in underground mining operations, minimizing the risk of rock falls and cave-ins

- Safety Barriers: Acts as a protective barrier in mining environments, helping to contain debris and protect workers from falling rocks

- Ventilation Control: Can be used to create partitions for ventilation systems, ensuring proper airflow and safety in underground mines

Choose Duke’s Wire Mesh & Metal for your mining projects and experience the quality and reliability of our Mining Mesh. Contact us today to learn more about our offerings and how we can help you achieve your project goals.

- Flat Sheets

Why Choose Us

Duke’s Wire Mesh Supply Services Ltd. is one of the most competitive metal manufacturers in North America. Our products are delivered to more than 160 countries and regions. We are looking forward to offering you high-quality services and goods for unbeatable prices. Call us for a quotation.

In-Stock

-

Product Overview

Mining Mesh is a grid of high-strength steel wires welded together at their intersections, forming a robust and reliable reinforcement structure. This mesh is specifically engineered to withstand the harsh conditions of mining operations, offering superior stability and protection.

Product Types

- Flat Sheets

- Sizes Available:

- Various sizes up to 7.5 feet wide and 35 feet long

- Applications: Ideal for reinforcing large surface areas such as mine walls and ceilings, providing excellent support and safety.

- Sizes Available:

- Rolls

- Sizes Available:

- Widths up to 8 feet (2.44 meters)

- Lengths up to 100 feet (30.48 meters)

- Applications: Suitable for flexible applications where ease of transportation and installation is required, such as temporary reinforcements and emergency repairs.

- Sizes Available:

Specifications

- Wire Gauges Available:

- 0 gauge (0.324 inches or 8.23 mm)

- 4 gauge (0.204 inches or 5.19 mm)

- 6 gauge (0.162 inches or 4.11 mm)

- 8 gauge (0.128 inches or 3.26 mm)

- Other thicknesses are customizable

- Mesh Sizes:

- 3×3 inches (75×75 mm)

- 4×4 inches (100×100 mm)

- Custom mesh sizes available upon request

- Materials:

- Carbon steel

- Class 3 galvanized steel according to ASTM A641 standard

- Customization:

- Thickness, opening size, and roll size can all be customized to meet specific project requirements.

Mechanical Properties

- Tensile Strength: Higher than 515 MPa

- Yield Strength: More than 450 MPa

- Welding Shear Strength: More than 50000 times the nominal area of the welded wire in square inches, offering 40% higher welding shear strength than industry standards (ASTM A1064-22)

Product Features

- Flush Cut Ends: Ends protrude no more than 1/8″ and no more than 3/16″ beyond the edge wire

- Third-Party Testing: All products are tested by well-known and reputable third-party testing labs

- Test Results: For detailed test results, please see the ASTM Quality Testimonies page

Installation Tips

- Cutting: Can be easily cut to size using wire cutters or power tools

- Mounting: Use appropriate hardware such as bolts, clamps, or brackets to secure the mesh in place

- Support: For larger spans or critical support areas, additional support structures such as rock bolts or anchors may be needed to prevent sagging or displacement

Compliance and Standards

- ASTM Standards: Manufactured according to relevant ASTM standards to ensure quality and consistency

- ISO Certification: Our production processes are ISO certified, guaranteeing the highest standards of manufacturing

Applications

- Mine Shaft Reinforcement: Provides essential support and stability to mine shafts, preventing collapses and ensuring worker safety

- Tunnel Support: Used in tunneling operations to reinforce tunnel walls and ceilings, offering enhanced structural integrity

- Roof and Wall Support: Offers critical support for roofs and walls in underground mining operations, minimizing the risk of rock falls and cave-ins

- Safety Barriers: Acts as a protective barrier in mining environments, helping to contain debris and protect workers from falling rocks

- Ventilation Control: Can be used to create partitions for ventilation systems, ensuring proper airflow and safety in underground mines

Choose Duke’s Wire Mesh & Metal for your mining projects and experience the quality and reliability of our Mining Mesh. Contact us today to learn more about our offerings and how we can help you achieve your project goals.

- Flat Sheets

Request A Quote

Duke’s Metal Industries is one of the most competitive metal manufacturers in North America. Our products are delivered to more than 160 countries and regions. We are looking forward to offering you high-quality services and goods for unbeatable prices. Call us for a quotation.