Perforated and expanded metals are the most common types used in various industries to achieve different tasks. Perforated metals are metal sheets punched with a pattern of holes. On the other hand, expanded metals are created by cutting and stretching a sheet of metal, leading to a mesh-like pattern. These two metals, copper and aluminum, have specific properties and features that make them appropriate for certain tasks.

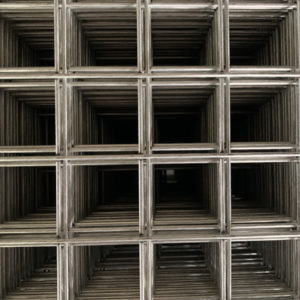

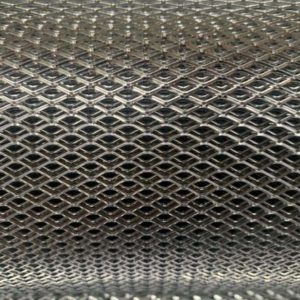

The fundamental characteristic that differentiates perforated metals from expanded metals is their manufacturing process. Perforated metals are produced using a punch press or laser cutting machine to generate holes of the required size and shape in the metal sheet. However, the expanded metal is cut and stretched to make a metal sheet with a diamond-shaped opening patterned like a mesh. As a result, the appearance, features, and performance of items made by these two methods are distinct.

Cost Comparison: Which is More Affordable – Perforated Metals or Expanded Metals?

Many factors can drive the cost of both perforated and expanded metals. The main factors influencing the price are the metal type and its thickness, the size of the sheet, the pattern or mesh complexity, and the amount required.

The process of perforated metal fabrication is more costly than that of expanded metals since it demands much more precision. Particular tools and highly qualified workers are doing the punching holes process, so this is the key reason for the cost increase. On the contrary, the production of expanded metals is very simple, and therefore, they are cheaper than the other products.

However, it is essential to consider the cost-effectiveness of each metal that is acceptable for your project. While perforated metals can be more costly initially, they provide more design flexibility. They are often better solutions than other options in some situations. While expanded metals can be inexpensive, in some cases, they can be disadvantageous in terms of design options and functionality.

Advantages and Disadvantages: Examining the Pros and Cons of Perforated Metals and Expanded Metals

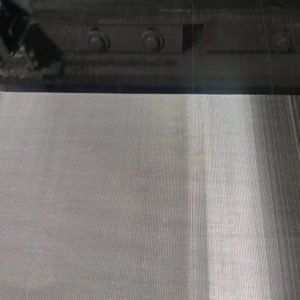

Perforated metals have many benefits, which make them a popular option for different industries. The special holes of the structure are responsible for ventilation, light transmission, and sound absorption. They can also produce increased viewability and decoration. Perforated metals can be designed in many ways, making complex designs and patterns possible. Also, they are good at strength and resistance, so they can be useful in cases that need structural integrity.

Despite the many benefits, perforated metals also have some demerits. The process of drilling the holes will weaken the total strength of the metal sheet, and thus, it will not be able to take the load as it used to. This may be a problem in applications where strength is a key factor. Further, the holes can weaken the metal’s ability to withstand corrosion and other weather effects. Surface treatment or coating needs to be applied correctly to avoid these problems.

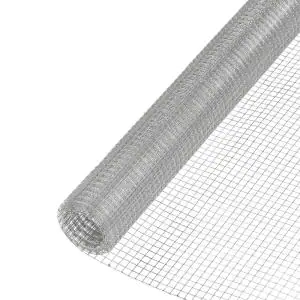

Apart from their versatility, they have other advantages that make them suitable for distinct applications. The mesh design combines strength and flexibility with the added advantage of airflow and light penetration. Expanded metals are lightweight, which makes them convenient for transportation and installation. Additionally, they provide good visibility and a high level of security because of the small mesh openings. Besides, increased metals are very corrosion resistant, which makes them suitable for outdoor applications.

A primary drawback of expanded metals is their limited design possibilities compared to perforated metals. The diamond-shaped holes limit the possible range of patterns. Additionally, expanded metals may not be as private or secure as the solid sheet due to the open characteristic of the mesh. On a few occasions, the stretching process can be responsible for slight variations in the dimensions of the metal sheet, which, in turn, can affect the fit of such sheet in some applications.

Analysis: Which Metal Type is Best Suited for Your Project?

The decision between perforated and expanded metals involves many aspects that need to be considered. The particular characteristics of your project, like the desired functionality, aesthetics, strength, and cost, will be very important in deciding the most suitable metal type.

Perforated metals are the best option for applications that involve accurate hole patterns, excellent ventilation, or increased visibility. They provide more design options and can be tailored to meet specific needs. Perforated metals are used in architectural projects, noise control systems, filtration systems, and decorative applications.

Contrary to this, expanding metals might be a better choice if your project requires good airflow, light transmission, and moderate strength. They can be found in fencing, walkways, security screens, machine guards, and shelving. The open mesh pattern of expanded metals offers good visibility while being strong and durable at the same time.

It should be noted that there might be cases where a combination of both perforated and expanded metals will be needed to get the desired functionality and aesthetics. In these cases, it is advisable to seek the opinion of a metal fabrication expert to know the best approach.